Sweating the Small Stuff

By Corinna Wu

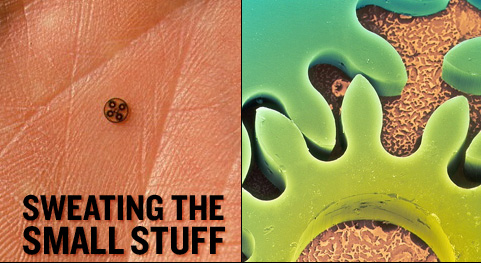

Photo left: A microgear mechanism on the palm of a hand. The high-precision cogs are made of nickel to 150 microns in thickness, and were created at the Wisconsin Center for Applied Microelectronics at the

University of Wisconsin. Photo right: Colored scanning electrol micrograph of microcogs forming a microgear mechanism. This could be used in microscopic sensors to detect acceleration, pressure, flow rate, and the presence of certain chemicals in a fluid.

NANOTECHNOLOGY OFFERS GREAT PROMISE FOR IMPROVING HEALTH AND CLEANING UP THE ENVIRONMENT, AND SCHOOLS ARE SCRAMBLING TO FIGURE OUT HOW TO TEACH IT.

Nowadays, the word “microscopic” is no longer sufficient to describe all things smaller than the eye can see. In some cases, only “nanoscopic” will do. It’s not hyperbole: Scientists and engineers know how to build and manipulate structures smaller than a millionth of a millimeter in size. At that scale, tiny bits of material—whether they be gold or gallium arsenide—behave differently than identical materials do in bulk. The chemical and physical properties change, requiring researchers to think in new ways about compounds that they’ve understood for decades.

And so it has been for educators too, thinking about how to teach the new field of nanotechnology to students. So far, the approaches taken have been as varied as the schools themselves. Some offer nanotechnology on a modest scale, involving students in individual classes and research projects. Others have developed entirely new degree programs, pulling in faculty and students from multiple departments. The National Science Foundation has funded many of these educational efforts through its Nanoscale Science and Engineering Program.

According to the NSF, the existing nanotechnology workforce numbers around 20,000, and the worldwide need will reach 2 million by 2015. One thing is certain: Industry has already expressed a desire for trained workers at all levels, and states see nanotechnology as an area of investment that will make them economically competitive. And in a show of federal support, President George W. Bush signed a law last December authorizing $3.7 billion of funding for nanotechnology research and development over the next four years.

Nanotechnology bridges many disciplines: chemistry, physics, materials science, engineering, biology, and medicine. This has challenged universities to break down barriers between departments and open new educational opportunities to students. It has also spurred them to include discussion of the societal and ethical implications of nanotechnology research—knowledge necessary to be a well-rounded scientist or engineer in the 21st century.

It’s a hot field all right, and it’s important to note that in terms of substance, there haven’t been any major accomplishments in research so far. It is widely believed that there will be, however. And there’s also the risk that researchers may label their proposals nanotechnology—when in fact it’s a stretch—to take advantage of money that’s fairly plentiful.

Many schools have technical courses in nanotechnology, available to upper-level undergraduates and graduate students. But this fall, Rice University is offering a new introductory class for first- and second-year undergrads—its first nanotechnology course aimed at a general audience. Kristen Kulinowski, executive director of public policy and education for Rice’s Center for Biological and Environmental Nanotechnology, designed the class along with Chris Kelty, an assistant professor of anthropology. It focuses on four broad themes: nanomedicine and nanobiology, nanotechnology devices, impact on human health and the environment, and issues of scale-up and manufacturing.

The course introduces students to the essential technical content of the field but also aims to put those facts into context. “The context part is about putting the enterprise of science, engineering, and technology development into its social perspective,” Kulinowki says. “So it is presenting issues of how science is funded, how scientists talk about the future vs. how science fiction writers talk, issues of patenting and intellectual property, and of course, environmental risk.”

Nanoparticles are small enough to enter cells, which gives them the opportunity to interfere with the cells’ biochemical machinery. They can absorb ultraviolet light and trigger chemical reactions. Scientists and engineers want to harness these properties to deliver drugs, clean up pollution, and improve consumer products, like sunscreen. But they also worry that nanoparticles can have unexpected effects on the environment and human health, especially if they’re used in medicine.

Kulinowski expects that the class will draw students from the humanities and social sciences as well as those with a scientific bent. The class is cross-listed under chemistry and anthropology, and satisfies university distribution requirements in science and social science. “Nanotechnology is stimulating a lot of very interesting discussions and debates that involve ethicists, philosophers, ecologists, economists,” Kulinowski says. The government and funding agencies have recognized that the societal and ethical implications of this new field must be explored right alongside research in the lab. So if these issues are being discussed and debated by experts, she reasons, “it makes a whole lot of sense that we should be doing that in the classroom.”

An introductory level class such as Rice’s can influence students to major in subjects they didn’t consider before. But those wanting a major in nanotechnology will have a difficult time doing so. According to Carl Batt, a professor of food science and co-director for advancing education at Cornell University’s Nanobiotechnology Center, few schools offer undergraduate majors in nanotechnology. Four-year, research institutions generally encourage students to major in one of the traditional scientific or engineering disciplines and earn a minor or concentration in nanotechnology by taking electives or doing focused research.

The idea is to allow students to major in whatever interests them and to make sure they have a strong foundation in chemistry, physics, biology, or engineering. For professors, there are also practical reasons: Batt says that establishing a new major is “a bureaucratic quagmire that would probably take you 10 years to sort your way through.”

MAKING IT A MINOR

Of course, establishing a minor is no small task either. Penn State University began planning for a minor in nanotechnology two years ago, says Stephen Fonash, professor of engineering sciences and director of the Nanofabrication Facility. The program just started this fall. “At Penn State, as is the case with most universities, you have to have approval of the college, the university senate—so it’s a long process,” he explains.

To earn the minor, sophomores and juniors take required overview courses and then choose “cafeteria-style” from higher-level classes in a variety of departments, even agriculture. Fonash expects students with a range of academic interests to take part. One big logistical challenge is giving all these undergrads hands-on lab experience, since a lot of nanotechnology work is done in a clean-room environment. Preparing to work in a clean room involves a lot more than just putting on a pair of safety goggles (see sidebar). As such, Fonash says, “The lab component is significant, but evolving.”

After getting a bachelor’s degree, many will join the growing workforce of trained nanotechnologists, already in demand by industry. Some graduates will continue on for an advanced degree to better prepare for a career in the field. Rice University, as well as other schools, has been building on its strong history of research by offering a professional master’s program in nanoscale physics. The university established the program in 2001 with a grant from the Alfred P. Sloan Foundation.

According to program coordinator Terry Pack, the professional master’s is meant for students who want training beyond a bachelor’s but don’t want to pursue a Ph.D. In the sciences—unlike in engineering—it’s unusual for a university to enroll a student interested only in a master’s. The degree has historically been awarded as a “consolation prize” to students who don’t pass their qualifying exams, Pack says. “The Sloan Foundation wanted to change this perception, because it dissuades people from gaining an advanced education in science and technology. So these professional science master’s [programs] were created to be a terminal degree.”

The program in nanoscale physics includes hard-core science classes—nanostructures, methods of experimental physics, computational physics—but also classes in management, science policy, and ethics. Then, students do a three- to six-month internship to apply what they’ve learned. “They’re not in a traditional Ph.D. program that’s more of a narrow-focused education,” Pack says. “It’s a broader education, so you can better apply it to the industry and a business environment.” The degree has been compared to an M.B.A., designed to train people who can usher the discoveries made in the lab into the real world.

FROM THE GROUND UP

Pushing new courses and degree programs through a university’s administrative machinery requires patience and perseverance. But the University at Albany in New York has accepted the challenge and taken it one step further: Earlier this year, it established a brand-new College of Nanoscale Sciences and Engineering. (It’s a graduate school; Students are expected to get a firm grounding in a traditional discipline before enrolling for an advanced degree.) The college operates out of Albany Nanotech, a complex of both public and private research and development labs.

In creating the entire academic program from scratch, the university structured the college to reflect nanotechnology’s interdisciplinary nature and strategic economic importance. Faculty belong to one or more “constellations”—think tanks constructed around themes—instead of traditional departments. “That encourages this interdisciplinary way of thinking and exchange of ideas between the different disciplines,” says Alain Kaloyeros, president of Albany Nanotech. “We didn’t want to create departments that turned out to be silos.” And instead of a dean who reports to the provost, the college has Kaloyeros, who reports directly to the university president, thus eliminating one layer of bureaucracy.

He also serves on the board that advises New York Governor George Pataki on the state’s investments in science and technology. In 2001, Pataki spearheaded the creation of six Centers of Excellence at public universities across the state, each revolving around one key subject area. The University at Albany, whose center focuses on nanotechnology and nanoelectronics, acts as the hub.

New York has contributed $350 million to Albany’s comprehensive enterprise in education, research, and technology deployment, Kaloyeros says, and three times that support has come from private investments. “The center started with research, and then it evolved between 2001 and 2004, adding the educational component.”

For Albany, investing in cutting-edge facilities is part of a strategy to attract top-notch students and faculty who might otherwise gravitate toward better-known universities. “If we decided to compete with MIT and Stanford up front…we couldn’t,” says Kaloyeros. “So we decided to play it in reverse—create the most exciting and state-of-the-art sandbox…and then go out and attract them.”

Like New York, Pennsylvania has also invested millions in nanotechnology education, with the hope of making the state competitive in this burgeoning field. Companies that deal in electronics, chemicals, and pharmaceuticals are eager to hire employees at all levels, especially people with associate degrees qualified to work as technicians.

That’s why Penn State has been collaborating with all of the two-year institutions in Pennsylvania—more than 30 schools—to prepare students for careers in nanotechnology. Funded as an NSF Advanced Technological Education Center, the university developed a kit for teachers at community colleges to enrich their regular classes. The kit gives students hands-on experience with the materials of nanotechnology—carbon nanotubes or gold nanoparticles, for example.

Students then spend a semester on the Penn State campus in an intensive “capstone” experience, designed to consolidate and focus what they’ve learned. They take six courses and train in Penn State’s nanofabrication facilities. Yet they continue to pay the tuition of their local college, with the state making up the difference. “Our educational philosophy is not to train students for one industry but to train them so they can go from industry to industry to industry—to give them a toolbox that they can use the rest of their career,” engineering professor Fonash says.

So far, 140 students have graduated from the program, many with associate degrees in nanotechnology. And they’ve had no trouble finding work, according to Fonash. “All of the major pharmaceutical companies in the Philadelphia area have one of these graduates.”

Demand from industry is what drives these educational collaborations. States that have strong research universities, local colleges, and a high-tech business community find that they have the essentials to forge these partnerships. The Penn State project is supported by state economic development initiatives as well as by federal grants from NSF. If the state didn’t pay the tuition difference between the local community colleges and Penn State, Fonash says, the semester-long capstone experience would be out-of-reach for many of the students.

Money is flowing into nanotechnology research from all sectors, public and private. And with funding going to education as well, industry hopes that the workforce will grow in step with their businesses—proving that the very small has potential to create big things.

Corinna Wu is a freelance writer based in Washington, D.C.

Category: Features